Specialty

Area of expertise: «Mechanical Engineering»

Specialty: «Industrial engineering»

Specialization: «Automated and robotic technological complexes in mechanical engineering “(Training of graduates on the basis of a junior specialist).

Entrance tests: specialty test.

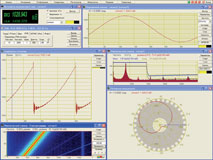

A modern process control system (automated process control system) is a multilevel man-machine control system. A dispatcher in a multilevel automated process control system receives information from a computer monitor or from an electronic information display system and acts on objects located at a considerable distance from him using telecommunication systems, controllers, and intelligent actuators.

One of the modern and fast-growing areas of progress is the automation and computerization of industrial production. The basis for technological re-equipment is the use of specialized sensors of all kinds (pressure, temperature, level, flow rate, mass, weight, chemical composition, and other parameters), which produce measurable results in the form of electrical signals that can be transmitted through various communication systems to control industrial computers. As a result of the analysis of the obtained parameters, specialized software and hardware complexes can either provide the operator with a visualization of the technological process or make pre-programmed decisions and intervene in the process by means of control mechanisms associated with the system. Thus, industrial systems are becoming qualitatively different, more manageable, stable, less dependent on the “human factor”.

One of the modern and fast-growing areas of progress is the automation and computerization of industrial production. The basis for technological re-equipment is the use of specialized sensors of all kinds (pressure, temperature, level, flow rate, mass, weight, chemical composition, and other parameters), which produce measurable results in the form of electrical signals that can be transmitted through various communication systems to control industrial computers. As a result of the analysis of the obtained parameters, specialized software and hardware complexes can either provide the operator with a visualization of the technological process or make pre-programmed decisions and intervene in the process by means of control mechanisms associated with the system. Thus, industrial systems are becoming qualitatively different, more manageable, stable, less dependent on the “human factor”.

Studying in this specialty, you will receive the qualification of an electrical engineer (bachelor, specialist, master) and become a specialist in the creation (design, manufacture) and operation of automation tools for technological processes in any industry.

Modern industry is distinguished by a high level of automation of all production processes – the process of designing machines, devices and any products, the processes of manufacturing machine parts and their assembly processes, information processing processes … At the same time, computer technology and modern information technologies are widely used.

You will be taught to use this technique and these technologies in the design, production and operation of modern automated process and production control systems in industry. For this, the Department of TMS has a sufficient amount of modern computer technology and qualified teachers – specialists in its use.

The demand for specialists in automated process and production control systems is constantly growing in all industries and not only in our country.

Area of expertise: «Mechanical Engineering»

Specialty: «Industrial engineering»

Specialization: «Automated production technologies “(Preparation of graduates on the basis of complete secondary education)

Entrance tests: Ukrainian, mathematics, physics (or foreign language).

Mechanical engineering technology at the end of the 20th century is an inextricable and equal combination of production and information technologies. At the present stage, the development of engineering technologies is primarily determined by the development of information technology engineering.

Information technology engineering is a key area for the development of engineering technology. In the last years of the 20th century, a new apparatus appeared, which is successfully used in mechanical engineering technology. It is based on the achievements of new information technologies. This is the apparatus of artificial intelligence methods, which allows using not only traditional mathematical models, but logical, logical and linguistic models, for the creation of which it is possible to use the natural technical language of a subject specialist. This has significantly expanded the range of tasks that can be formalized and, therefore, provided to a greater extent with tools for representing technologies as scientific knowledge.

All technological advances, from the design of new machines to their speedy implementation in metal, are accumulated in a single science in technology. At present, the level of well-being and the role of any country in the world is primarily determined by the level of its technological development. It is becoming obvious that the leading nation of the 21st century will be the one that will create the most efficient system of machine-building production. The fate of our country, access to an advanced technological level, and the competitiveness of domestic technology in the world market depend on future engineers.

Now the work of a process engineer at the enterprise has radically changed. The proliferation of new machining centers and automatic lines controlled by a computer, the emergence of computer-aided design and production control systems at almost all machine-building enterprises has led to the fact that a modern technologist is an engineer who creates new equipment, relying on fundamental technical education and widely using computer technologies.

Mechanical engineering technology is high-performance processing methods, the use of new highly efficient materials, new computer technologies. We teach work in the most modern CAD / CAM / CAE systems KOMPAS 3D, AutoCAD, T-FLEX. Graduates are able to solve the most complex engineering problems: create solid models and assemblies, develop working drawings of products in a dialogue mode, optimize the technological process using modern mathematical methods and systems of mathematical modeling, simulation of machining and control programs for CNC machines, and more.

Young engineers, having received our education, quickly adapt to production conditions and become leading specialists, and students who have shown themselves in the research field continue their studies in graduate school.

Area of expertise: «Mechanical Engineering»

Specialty: Applied mechanics

Specialization: “Metal-cutting machines and systems” (Training of graduates on the basis of a junior specialist)

Entrance tests: specialty test.

Aesthetic qualities are formed from the first stages of design, and the beauty of a machine cannot be created due to some additional elements introduced specifically for beauty – this is the main difference between decorative arts and industrial design. It is determined by the expediency of machines, rationality and the conformity of its form to the functional purpose and aesthetic requirements. The expediency of a machine means its usefulness at the present level of development of society; conformity of the form to functional and aesthetic requirements is the maximum convenience, safety and positive emotional impact on a person during operation; the rationality of the machine shape is the consistency of the design, successful design solutions, the progressive technology of manufacturing and assembly of parts and assemblies.

The aerodynamic shapes of modern airplanes look beautiful. The appearance of the turbine rotors clearly demonstrates the possibility of transferring large forces and this ability is emphasized by the grace of their shapes. In both the first and second cases, the beauty of the forms is based on rigorous engineering calculations. The form, for example, of jewelry, decorative ceramics is not substantiated, but is created by the artist.

Our specialization is designed to produce engineers who can simultaneously apply modern software, artistic product design techniques and rigorous engineering calculations in the design of modern automated process equipment. Automated technological equipment should be understood as metal-cutting machines and systems equipped with “electronic brains” in the form of on-board computers. Modern trends in the development of mechanical engineering suggest that it must quickly adapt to the realities of the market, and the main problem with such a formulation of the question is equipment changeover, which is solved through the use of computers at all stages of production preparation.

We will teach you to master modern automation systems for design work: Compass 3D, T – Flex, AutoCAD, SolidWorks, which allow you to solve design and design problems.

Specialists in the design, design, production, marketing, operation and repair of metalworking equipment will always find a job, since this equipment is available and is used in all sectors of the national economy.

Our students