Maxym Svitlychnyi

Technical Director of the Kharkiv Jewelry Factory AGNI

Zvereva Vera Serhiivna

Researcher at the NTK “Institute of Monocrystals of the National Academy of Sciences of Ukraine,” Kharkiv

Semilet Olena

Head of the Production Laboratory and WTC at “Yugcement,” a branch of Dyckerhoff Cement Ukraine, Oleshanske, Mykolaiv region

Borova Valeriia and Anastasia Hryvtsova

Engineer-Laboratory Technician and 5th-year Student at Kharkiv Tile Factory PJSC

Halyna Serebriakova

Metrologist at Kharkiv Tile Factory PJSC

Pokroieva Yana Oleksandrivna

Head of the Incoming Inspection Service at Kharkiv Tile Factory PJSC

Oleksii Shevtsov

Postgraduate Student at Harbin Polytechnic University

Riabinin Oleksandr

Chief Engineer at Kharkiv Tile Factory PJSC

Kushchenko Pavlo Oleksandrovych

Deputy Director of UkrNDI Refractories named after A.S. Berezhnyi, Ph.D. in Engineering

Yaits’kyi Serhii Mykolaiovych

Director of Lysychansk Glass Factory

Svitlychnyi Yevhen

Ph.D. in Engineering, Senior Researcher at the National Science Center “Kharkiv Physico-Technical Institute”

Svitlana Gretsai

In 2004, I graduated from the Department of Ceramic Technology, Refractories, Glass, and Enamels at NTU “KhPI” and worked as the Head of the Research and Development Department at JSC “Slobozhanska Building Ceramics.”

In 2005, I was appointed as the Head of the Laboratory at the Austrian company “Wienerberger Ukraine.” In the same year, I completed an internship at the Hennersdorf laboratory, where I gained valuable experience in raw material research and European methodologies. I worked at Wienerberger until 2007.

In 2008, the company “Kerameya” was established, becoming the first company in Ukraine and the former USSR countries to produce clinker ceramic bricks. I held the position of Head of the Laboratory, where we developed new batch mixtures and new colors for products. In 2010, our company launched clinker ceramic paving stones, which were also a new product on the building materials market. Currently, I am the Chief Technologist at “Kerameya,” a company that is constantly developing and surprises its consumers every year with new products, with plans to never stop at what has been achieved but to continually improve.

I would like to express my immense gratitude for the knowledge I gained at the department, especially to Mykhailo Rishchenko and Olena Fedorenko.

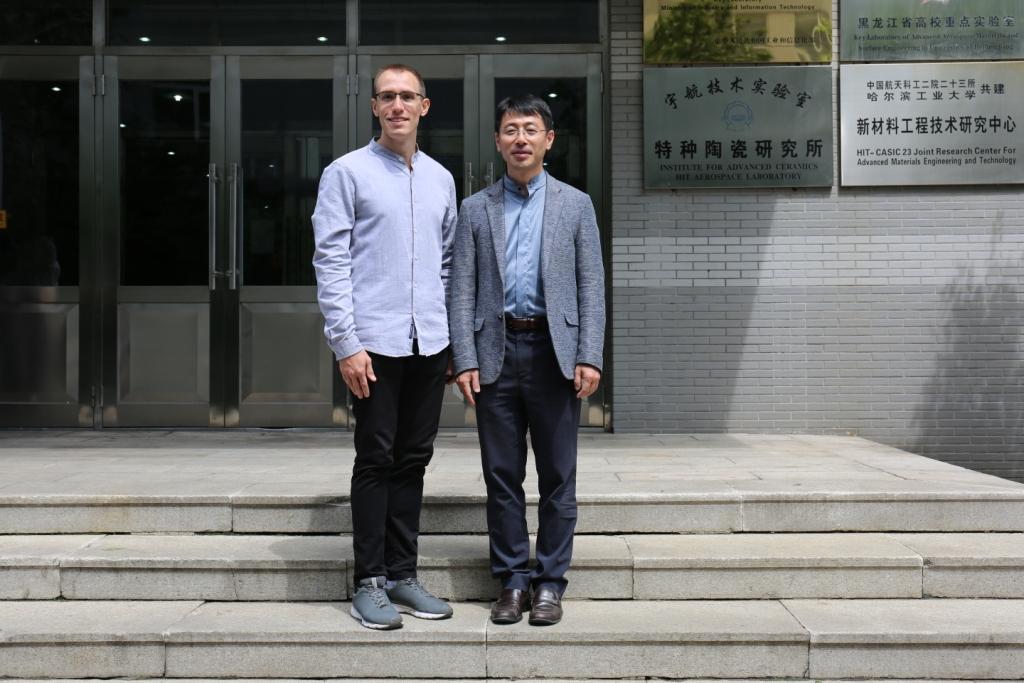

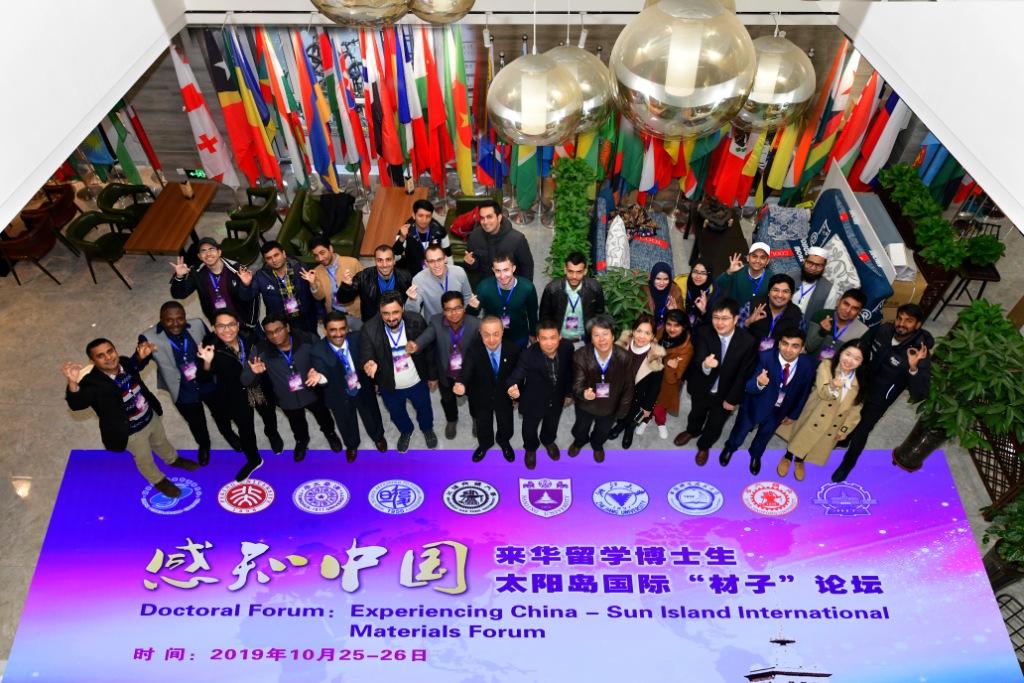

Oleksii Shevtsov

I entered the Department of Ceramic Technology, Refractories, Glass, and Enamels after graduating from the Bakhmut Industrial College. My student years at NTU KhPI were, without exaggeration, among the best in my life. The university provides an opportunity for development both in science and in public life. For example, during my studies, I worked for more than three years in the student trade union and headed the trade union bureau of my chemistry faculty, which also gave me immense life experience. I can confidently say that the five years I spent at the department were not in vain. Studying here was very interesting, warm, and fun, like a family. In my senior years, I became fascinated with materials science and actively engaged in scientific research, the results of which were recognized with awards in student scientific competitions.

In 2017, I graduated from the Master’s program at the Department of Ceramic Technology, Refractories, Glass, and Enamels at NTU “KhPI” with honors. Thanks to the guidance of my scientific advisor, Professor Olena Fedorenko, and the help of Dean Serhii Leshchenko, I participated in a competition and received a scholarship from the Government of the People’s Republic of China for a 4-year full scholarship for doctoral studies at Harbin Polytechnic University—one of the top universities in the country, ranking among the top 10 engineering universities in the world.

Currently, I have been living in China for almost three years, where I am studying and working on my dissertation. During this time, I have improved my proficiency in foreign languages (Chinese and English), gained experience living and studying in another country, and made new friends.

I have the opportunity to work in laboratories equipped with state-of-the-art technology, which many scientists dream of. I have already participated several times in international forums and congresses, which has allowed me to develop contacts with the global scientific community.

All of this is thanks to my studies and graduation from the Department of Ceramic Technology, Refractories, Glass, and Enamels at NTU “KhPI,” where the lecturers stand out for their high professionalism and provide fundamental knowledge in the field.

Based on my experience, I wholeheartedly recommend all applicants to choose this department. Thanks to the knowledge and practical skills gained here, you will be able to find work not only in Ukraine but also abroad. Make the right choice!

Thank you to the esteemed lecturers of the department, and I wish success to all students!

Oleksandr Pylypchatin

In 2011, I graduated with a Master’s degree from the Department of Ceramic Technology, Refractories, Glass, and Enamels. Currently, I lead the research department in the “Plinfa” group of companies, which focuses on the development of ceramic material production technology and its implementation according to the individual needs of each case.

My studies at NTU “KhPI” started quite unexpectedly, but I am incredibly happy that I ended up at this university and in this specialty.

I met my future lecturers during the submission of original documents. They made a pleasant impression on me. They were serious yet kind, and to this day, I have a very positive attitude towards them, even though our views on the world and the learning process differ in many respects.

In general, the lecturers at the department are people with a vast wealth of knowledge in various fields. In my opinion, they not only teach but also try to cultivate in us what teachers in school were not able to do.

My friends in the group are people with the most diverse goals. I’m still amazed at how we all ended up in the same boat. I am very proud to know each of them. These are wonderful people, each with their own uniqueness. I enjoy remembering every moment spent with them, whether it’s a snack before class or a debate on any topic (especially during class).

I really enjoyed the classes taught by lecturers who gave us the opportunity to search for answers and solutions within our small circle. Classes in our specialty were undoubtedly the best. Not only because of the different attitude of the lecturers towards us, although that certainly plays a role, but more because you don’t have to relearn school material, and because there are fewer people, and you are listened to. With any problem, you can turn to the lecturers, the group leader, or classmates, who, if they can’t help, will at least listen, give some advice, or direct you to look for the answer elsewhere.

During my studies, I not only acquired the necessary knowledge and skills in the field of binders, ceramics, refractories, glass, and enamels but also learned the importance of constantly updating knowledge and self-educating. Without this, it would have been difficult to achieve the success I have today.

I must say that it was hard at first to work, as over the six years of my studies, I got used to “absolute” freedom. And now, there were incomprehensible terms, unclear demands, and what to focus on, etc. It was incredibly difficult to adapt to the new conditions, but now, when there is no need to study material meant for the entire semester in two days, it’s not as difficult anymore…

I am glad that I stayed to study at our university and at our department. I have no regrets about submitting my documents to KhPI for the ceramic department. I am proud to have met many wonderful people, and I had a great time both during and between classes.

Natalia Tsapko

I am a hereditary inorganic chemist!!! My parents met while studying at KhPI. Later, my father, after graduating from the Department of Ceramic Technology, Refractories, Glass, and Enamels, worked for many years in the research group at the refractories laboratory. So, even as a child, I found myself in the ceramics department’s “holiest” places, where I saw presses, mills, and kilns for firing ceramic and refractory materials. To keep me from disturbing the work too much, I was given photos of material microstructures, allowed to play with “stones” in the mineralogy museum, and peek into microscopes, etc. Therefore, it’s no surprise that when it was time for me to apply to a university, the question was almost decided – KhPI, Faculty of Inorganic Technology, Department of Ceramic Technology, Refractories, Glass, and Enamels!

I attended preparatory courses for a whole year, participated in chemistry and Ukrainian language Olympiads, passed exams at the preparatory courses, and went through the interview… And finally, I was on the list of accepted first-year students!!!

September 1, 2000! How long ago that was… But in my memory, it feels like just yesterday I was welcomed as a student, meeting my classmates, and experiencing so many other different things. The time during my studies was full of variety: interesting, difficult, and fun, but never boring! I was lucky to have Elena Yurievna Fedorenko as our group’s curator, and we could always turn to her with any questions about studies or anything else.

Mykola Kuryakin

Випускник кафедри технології кераміки, вогнетривів, скла та емалей НТУ «ХПІ» 2009 р.

Graduate of the Department of Ceramic Technology, Refractories, Glass, and Enamels at NTU “KhPI,” 2009.

I entered graduate school and defended my candidate dissertation titled “Light and Self-Cleaning Calcium-Borosilicate Glass-Composite Coatings for Household Heating Equipment” in 2013. I am a Candidate of Technical Sciences and currently work as a Junior Research Fellow at the department.

In May 2015, as part of the Ukrainian delegation, I participated in the 23rd International Enamellers Congress in Italy. The congress took place in Florence, with representatives from major companies and corporations, including LG, Ferro, Colorobbia, Wagner Itep, and others. We represented our university with a report on “Glass-Enamels for Light and Self-Cleaning Coatings.” Technical excursions were organized to the Indesit factory in Fabriano and Ferrari in Maranello. As part of the cultural program, we attended a symphonic orchestra performance at the Teatro della Pergola, walked through the Giardino di Boboli gardens, visited the Oliveto Castle, and toured the Bargello Museum, which houses the largest collection of Renaissance sculptures in Italy (14th-17th centuries), including works by Donatello, Michelangelo, Benvenuto Cellini, Luca and Simone della Robbia, as well as other great masters.

Anastasia Borysenko

After graduating from the Department of Ceramic Technology with a Master’s degree, I have been working since 2014 at the gas production management company “Poltavahazvydobuvannya” in the water, oil, and condensate analysis laboratory.

The knowledge and skills I acquired during my studies have proven to be useful, although my work is not directly related to ceramics, glass, or refractories production. At the department, I not only gained specialized knowledge but also learned how to work with documentation and process data on a computer. Moreover, we were taught that one should never stop striving for improvement. As soon as you stop keeping up with new trends and expanding your knowledge base, you stop being a professional and become uninteresting to employers.

Vira Zvyeryeva

In 2014, I graduated from the Master’s program in “Refractory Nonmetallic and Silicate Materials” at the Department of Ceramic Technology, Refractories, Glass, and Enamels. I completed my pre-diploma practice at the Institute for Scintillation Materials of the National Academy of Sciences of Ukraine in the laboratory of refractory scintillation materials. After defending my thesis, I was invited to work as a leading engineer in this laboratory. Today, I combine my job in this position with my studies at the Institute of Scintillation Materials (ISMA) of the National Academy of Sciences of Ukraine in the postgraduate program. I really enjoy what I do – it is never boring here. Every day we move forward, expanding our horizons and scientific interests, tackling new tasks, developing new materials and methods for their production, and describing various physical effects and scintillation mechanisms in the materials we create.

In just six months, I already have experience working with cutting-edge equipment in a modern chemical laboratory and communicating with international colleagues.

P.S. What are scintillators?

Scintillators are monocrystals that convert ionizing radiation into visible light. They are used in medical and industrial tomographs, X-ray machines, well logging in geology, customs control and radioactive substance monitoring systems, dosimetric control devices, high-energy physics (e.g., PbWO4 in the Large Hadron Collider), and experiments looking for rare events, such as the search for dark matter and neutrinoless double beta decay.

Our goal is to create new materials with improved scintillation properties to expand the range of this class of materials and extend their application areas, as well as increase the lifespan and performance quality of currently used scintillators.

Our institute successfully collaborates with various international laboratories and manufacturers from Italy, Switzerland, the UK, France, China, Japan, South Korea, India, Belarus, and Russia. Specifically, our laboratory works with major companies like Gran Sasso (Italy), CERN (Switzerland), as well as scientists from laboratories in China, Australia, the UK, and Korea.

Mykola Vabyshchevych

I graduated from the Department of Ceramic Technology, Refractories, Glass, and Enamels at NTU “KhPI” in 2014.

During my studies, I set a goal to acquire a high-quality specialized education that would allow me to work at leading companies in the ceramics industry. The topics of my thesis works for both my Bachelor’s and Master’s degrees were directly related to the operations of ceramic tile production at PJSC “Kharkiv Tile Plant” – the largest and most modern tile factory in Ukraine, which produces a variety of ceramic tiles.

The high level of training provided by our department enabled me to achieve positive practical results, which were recognized by the specialists at the enterprise. During the graduate presentation, organized annually by the department, I was offered a job at PJSC “KTP.”

Given my lack of experience in the ceramic industry, I agreed to the offer. Thus, I began gaining practical skills that were also well-compensated. After the internship, I was appointed as a workshop master for the rectification of ceramic granite. Currently, I work as a process engineer, and in my free time, I play in the factory’s volleyball team.

Along with me, my classmates Valeriya Borova and Daria Shemet also joined the company, where they work in the frits melting and glaze preparation laboratories.

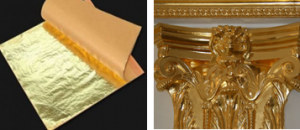

Serhiy Kanytskyi

I graduated from the Department of Ceramic Technology, Refractories, Glass, and Enamels at NTU “KhPI” in 1995.

I am a successful entrepreneur and a qualified specialist in the development and production of liquid gold preparations, mosaic gold smalt, and gold leaf.

The fundamental knowledge I gained at the department, along with my second higher education from the Higher Gemological Educational School (Idar-Oberstein, Germany), became a solid foundation for creating scientific-production enterprises that manufacture liquid gold preparations used for the artistic decoration of porcelain and faience products and glass; gold smalt, a universal material for creating monumental mosaic panels, and the interior and exterior decoration of museums and temples; as well as gold leaf, thin gold sheets (from 0.1 to 0.25 microns thick) used in gilding church domes, sculptures, and boxes.

Use of liquid gold preparation

Gold leaf

Gold smalt, mosaic

Kateryna Dainieko

During my studies at the Department of Ceramic Technology, Refractories, Glass, and Enamels at NTU “KhPI” from 2005 to 2011, there was never a moment when I regretted my decision to join the university. My academic days, the group that became my second family, and participation in conferences across Ukraine and abroad — five and a half years flew by like a single day.

One of my brightest memories of student life was participating in a competition supported by the Presidential Fund of Leonid Kuchma for the best scientific work on the topic “Let’s Make Ukraine Energy-Efficient,” where together with postgraduate student M.A. Chyrkina, we performed excellently and became laureates of the First Prize.

From 2011 to 2014, I was a postgraduate student at the department, working on the development of low-temperature electrical porcelain technology. During my postgraduate studies, I participated in international scientific conferences (in Miass, Chelyabinsk region; Moscow) and interned at Wismar University of Applied Sciences (Wismar, Germany).

At Lake Turgoyak during a business trip to the Institute of Mineralogy of the Ural Branch of the Russian Academy of Sciences (Miass) for participation in a scientific conference.

Serhiy Piven

In 2008, I completed my studies at the Department of Ceramic Technology, Refractories, Glass, and Enamels of NTU “KhPI”.

Currently, I work as the head of the customer technical support department at UMG.

The company is engaged in the extraction and sale of high-quality clays used for the production of ceramic tiles, sanitary-technical, household, and electrical porcelain, refractories, etc. Our company also deals with the sale of ash-slag materials used in cement and concrete technology, as well as microspheres for the production of refractories, drilling fluids, and in the paint and varnish industry.

The knowledge I acquired at the department allows me to have a comprehensive understanding of the production processes in which these materials are used, which significantly helps in promoting our products in both domestic and international markets.

Marina Chirkina

I graduated with a degree in “Chemical Technology of Refractories and Silicate Materials” in 2007, receiving a diploma with honors, and earned the qualification of engineer-technologist-researcher. In the same year, I entered graduate school, where I worked on my dissertation titled “Low-Temperature Household Porcelain Based on Quartz-Feldspar Raw Materials of Ukraine,” supervised by Prof. O.Yu. Fedorenko.

In 2010, by submitting a collective work to the competition “Let’s Make Ukraine Energy-Efficient,” organized by the Institute for Strategic Studies with the support of the “Presidential Fund of L. Kuchma ‘Ukraine,'” we became laureates of the first prize.

During my studies, I also obtained a second higher education in “Intellectual Property” at the Intersectoral Institute of Postgraduate Education at NTU “KhPI,” which enables me to work as an intellectual property specialist in the patent department of any university or research institute.

After defending my dissertation in 2012, I have been working at the National University of Civil Protection of Ukraine, a leading educational institution of the State Emergency Service of Ukraine. It is one of the largest and oldest fire-rescue training institutions not only in Ukraine but also among post-Soviet countries. I work as a senior lecturer in the Department of Special Chemistry and Chemical Technology at the Faculty of Operational-Rescue Forces. I teach cadets the following disciplines: “Chemistry,” “Fundamentals of Chemical Production Design,” “Technology, Equipment, and Design of Environmental Protection Systems.”

My job is not the easiest, but it is very interesting. I enjoy interacting with students and passing on my knowledge to them, just as the teachers of my beloved Department of Ceramic Technology, Refractories, Glass, and Enamels once passed on their knowledge to me, for which I am very, very grateful.

Konstantin Firsov

I completed my master’s degree at the Department of Ceramic Technology, Refractories, Glass, and Enamels in 2006 and entered the postgraduate program at NTU “KhPI.” Under the guidance of Professor O.Yu. Fedorenko, I prepared and defended my dissertation in 2010 on the topic “Ceramic Granite Based on Quartz-Feldspar Raw Materials from the Azov Crystal Massif” and received the degree of Candidate of Technical Sciences in the specialty 05.17.11, Technology of Refractory Non-Metallic Materials.

Currently, I work as a research associate at a private manufacturing company specializing in the production of glass hydrometers and thermometers for industrial and household use. During my work, I developed and implemented a unique technology for the serial calibration of industrial hydrometers by the hydrostatic weighing method, which is unique for the CIS countries and successfully competes with European analogs in terms of speed and quality of calibration.

This technology significantly reduces the error of the produced hydrometers and greatly simplifies and makes the calibration process for “heavy” range hydrometers safer by eliminating dangerous and aggressive liquids.

In addition to my main role as the head of the calibration department, my duties also include participation in the development of new products for the company, improving technological processes, preparing for printing, and maintaining contacts with foreign partners, particularly with companies in the PRC, with whom we have been working closely for the past few years. I am grateful to the faculty of the department and my Alma Mater for the high-quality education and excellent specialty.