ROLLER BEARINGS OF AN INCREASED TECHNICAL LEVEL FOR HEAVY DUTY OPERATIONS

Brief description of performed works

The problem of increasing the technical level of heavy-duty roller bearings (HDRB), provided that the improvement of one or more quality indicators does not cause the deterioration of the rest, requires:

- creation of a methodology for the systematic display of a set of indicators of the quality of the construction of HDRB at the stages of design and modernization;

- development of new and improvement of known calculation models of the interaction of parts and structural elements of the HDRB;

- substantiation of new constructive and technological solutions of HDRB based on comprehensive scientific research.

The methodology created for the systematic improvement of the technical level on the example of cylindrical HDRB significantly expanded the possibilities of designing new and modernizing known structures on the basis of a universal hierarchical system of quality indicators, system analysis and objective selection of the most effective structural and technological solutions.

As a result of the performed studies and reasonable constructive solutions, the system index of the technical level of the modernized design of the roller heads as part of the high-speed train rail transport box has been increased by 20.5% compared to the basic design. The effect of modernization was achieved thanks to:

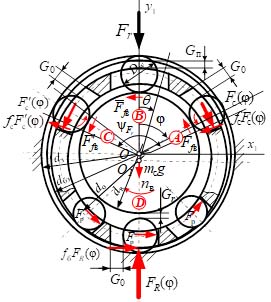

- an increase in the number of rollers, which ensured an increase in the calculated values of the dynamic load and the resource of the roller heads by 10.5 and 39.6%, respectively;

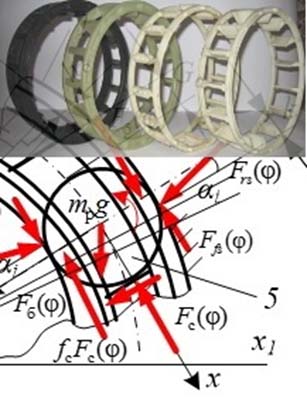

- improvement of the internal dynamics of the roller plates with a separator of improved geometry and a corresponding reduction by 9…12% of the operating loads, which ensured an increase in the probability of trouble-free operation of the separator of the roller plates of passenger and freight cars by 20…40% and 50…80%, respectively;

- replacement of material (brass with polymer) and modification of the geometry of the separator design with a grease-retaining profile of the friction surfaces, which made it possible to stabilize the temperature of the modernized designs of the roller heads in the high-speed (up to 250 km/h) passenger trains of Ukrzaliznytsia.

The following types of roller rollers of a higher technical level for heavy duty operation have been introduced at JSC “KHARP”: 30-42726E2M, 30-232726E2M, which are used as part of boxcars for freight and passenger cars, rollerboards 30-42728EM, 30-232728EM as part of boxcars of electric trains and rolling stock 30-32532ЕМ, 30-152532ЕМ, 30-42536ЕМ, 30-52536ЕМ, 30-152536ЕМ.

PUBLICATIONS

1. Gaydamakа A. Improving the Design of Bearings Separators for Raising the Technical Level. Eastern-European journal of enterprise technologies. 2016; 6, No. 1 (84). 4-8. https://doi.org/10.15587/1729-4061.2016.85849

2. Gaydamaka A, Klitnoy V, Muzikin Y, Tat’kov V, Hrechka I. Construction of a Model for the Distribution of Radial Load Among the bearing’s Rolling Bodies. EEJET 2018; 6, 39-44. https://doi.org/10.15587/1729-4061.2018.149964.

3. Gaydamaka A, Kulik G, Frantsuzov V, Hrechka I, Khovanskyi S, Rogovyi A, Svynarenko M, Maksimova M, Paraniak N. Devising an engineering procedure for calculating the ductility of a roller bearing under a no-central radial load. Eastern-European Journal of Enterprise Technologies. 2019; 3. 6-10. DOI 10.15587/1729-4061.2019.168145.

4. Gaydamaka A, Klitnoi V, Dobrotvorskiy S, Basova Y, Matos D, Machado J. A Systematic Approach for Energy-Efficient Design of Rolling Bearing Cages. Applied Sciences. 2023; 13(2):1144. https://doi.org/10.3390/app13021144