At the beginning of November, the excellent weather allowed us to conduct field tests of our new CRT01 cyber-physical mobile platform. We chose the beautiful inner courtyard of our Electrical Engineering Building as the test site. The area features varied terrain: a paved path, a dirt road, and a small grassy hill with trees and shrubs. This setup allowed us to test the platform’s mobility under different conditions without needing to search for specialized testing grounds near our lab.

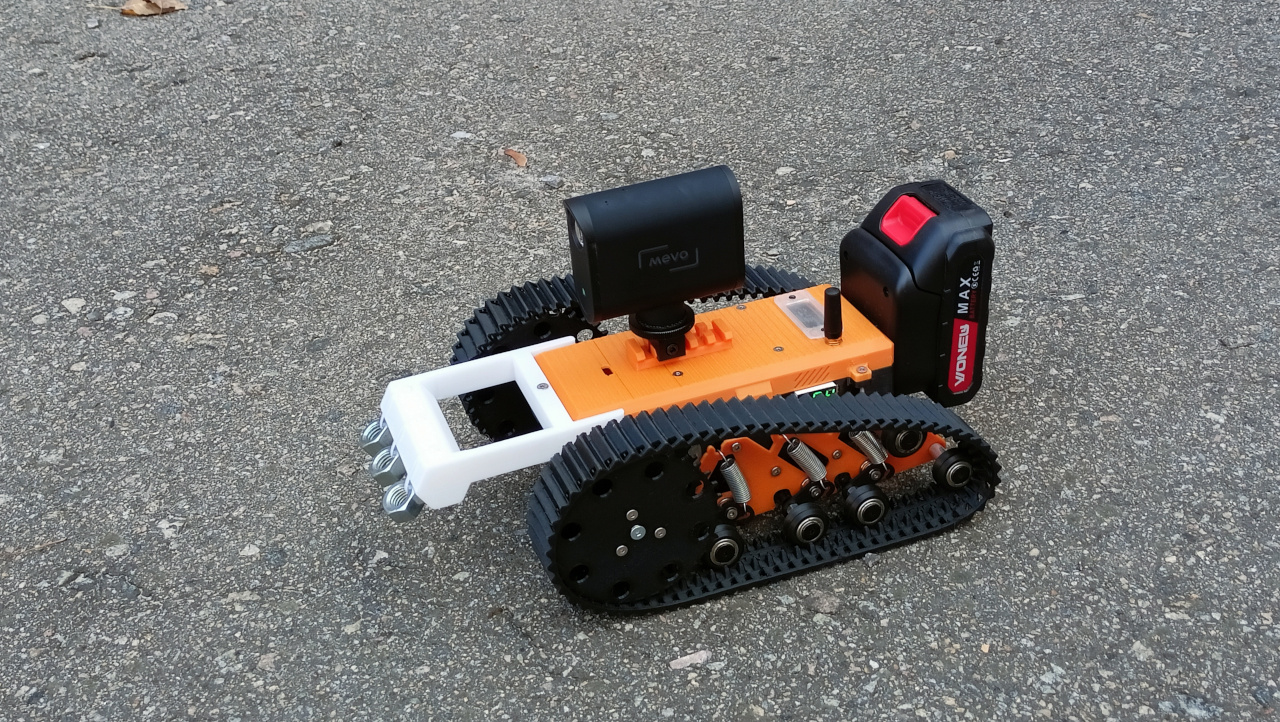

The platform we developed uses a tracked chassis, controlled wirelessly via the ESP-NOW protocol from a touch-screen console based on the ESP32 platform.

A key feature of the CRT01 is the extensive use of 3D-printed mechanical components. The body, mounting elements, levers, wheels, and even the tracks were printed using a flexible rubber-like filament.

During the test runs, we evaluated the platform’s mobility and maneuverability across different types of terrain, its obstacle-crossing ability, and its speed performance. We also checked the reliability of the connection between the console and the platform, as well as the use of an onboard autonomous webcam for real-time recording and streaming directly from the platform.

During testing, we observed some weight-balance issues, especially when moving on inclines and over obstacles. There were also minor challenges with stable movement when very rigid objects got caught between the tracks and wheels.

Overall, the platform demonstrated very good performance on rough terrain, while crossing obstacles, and maneuvering at high speeds on paved surfaces. We also noted its excellent energy efficiency. The research team was satisfied with the results and identified further directions for improving the platform.